Breadcrumb

- Home

- Product Search

- Thermal Liteblock

- Liteblock -140mm- Solid

- Liteblock -140mm Soap Bar

- Thermal Liteblock

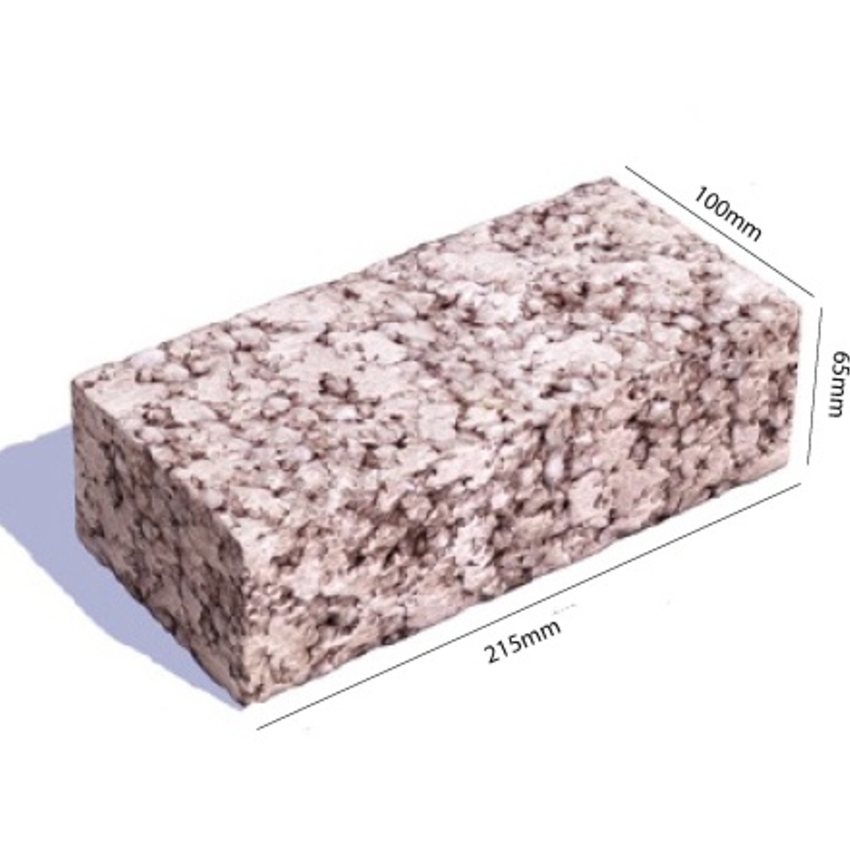

- Liteblock stock brick

- Thermal Liteblock 100mm Solid

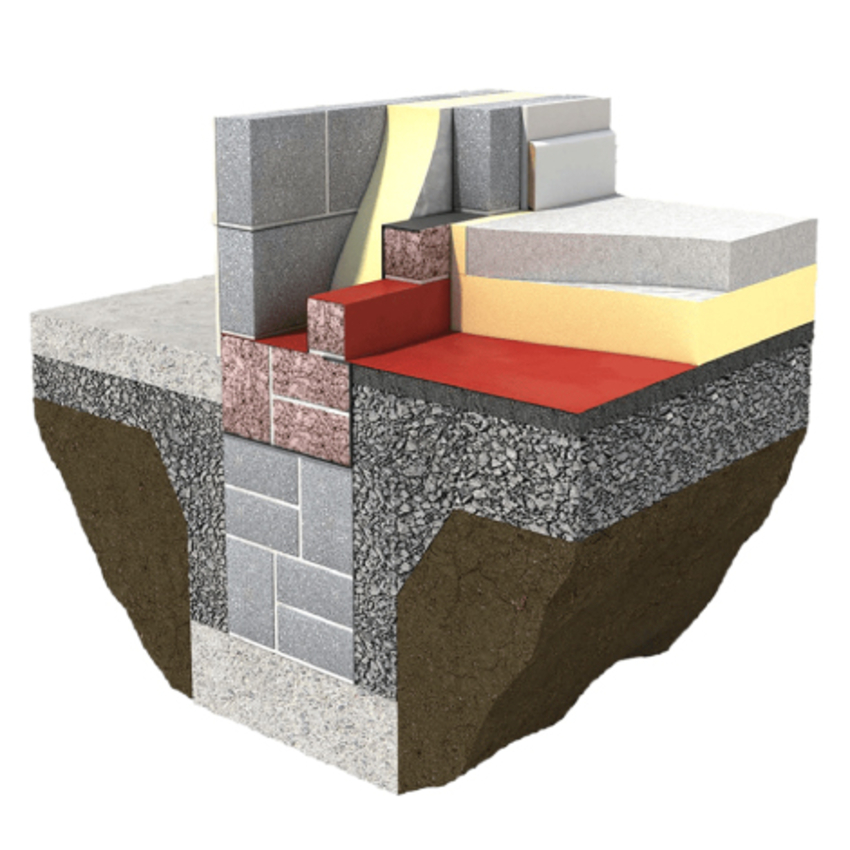

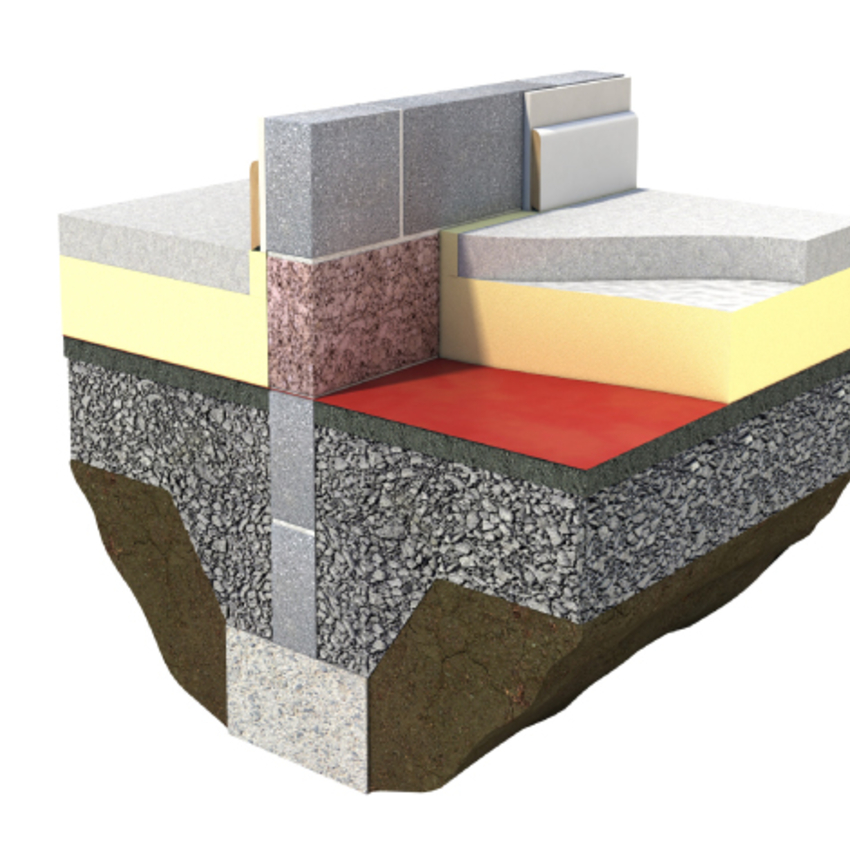

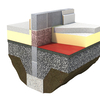

- Thermal Liteblock - below slab

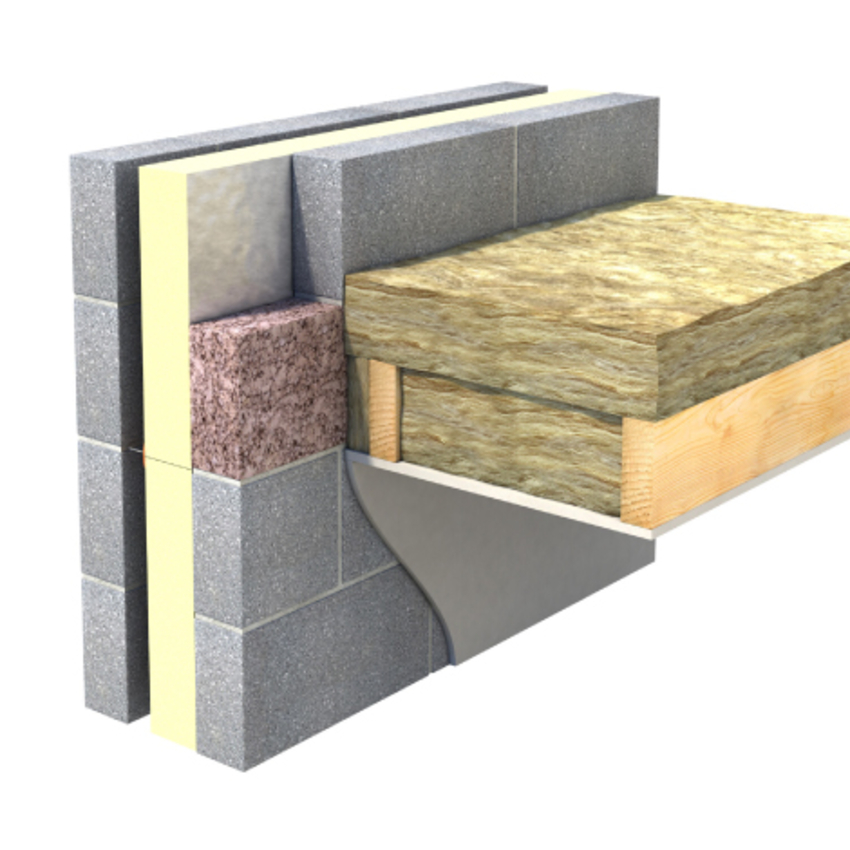

- Thermal Liteblock eaves detail

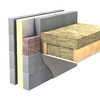

- Thermal Liteblock jamb detail

- Thermal Liteblock - Seperating wall B-detail

- Thermal Liteblock seperating wall- A- detail

- Thermal Liteblock- Seperating wall - C- detail

- Thermal Liteblock - Gable- detail

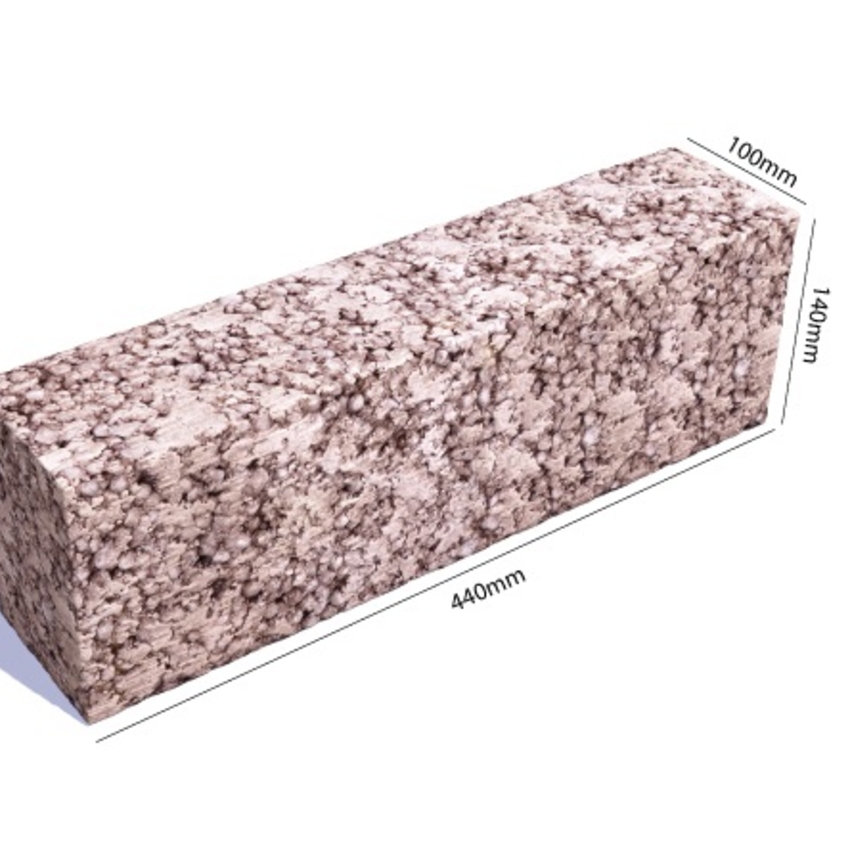

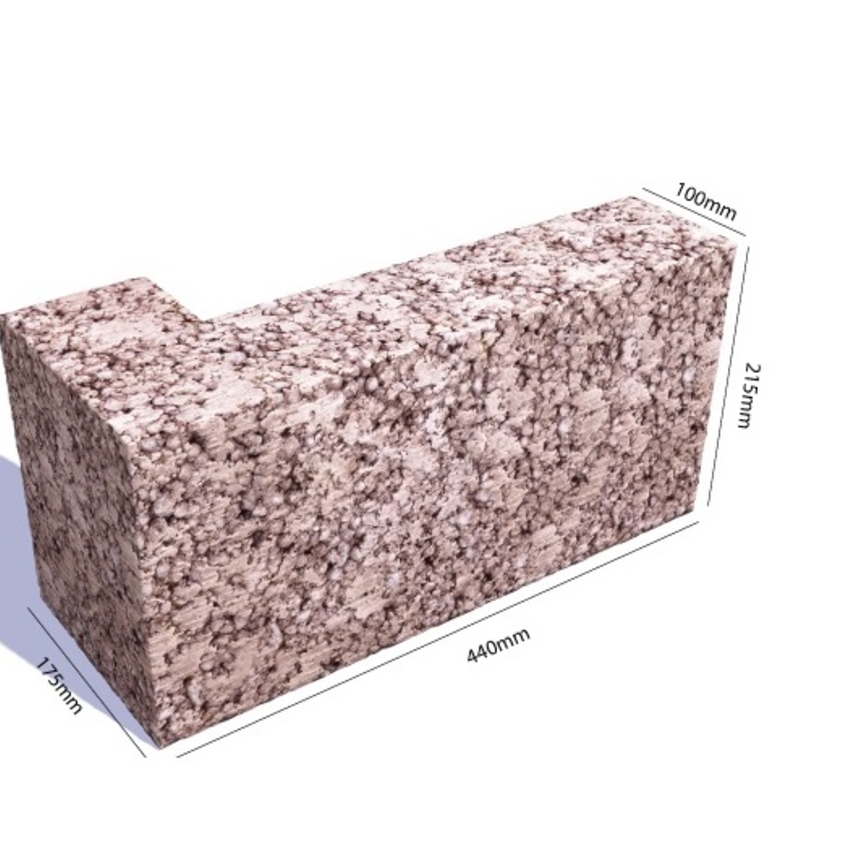

- Liteblock -100 -175mm - Cavity- Closer

- Liteblock -100 - 150mm- Cavity- Closer

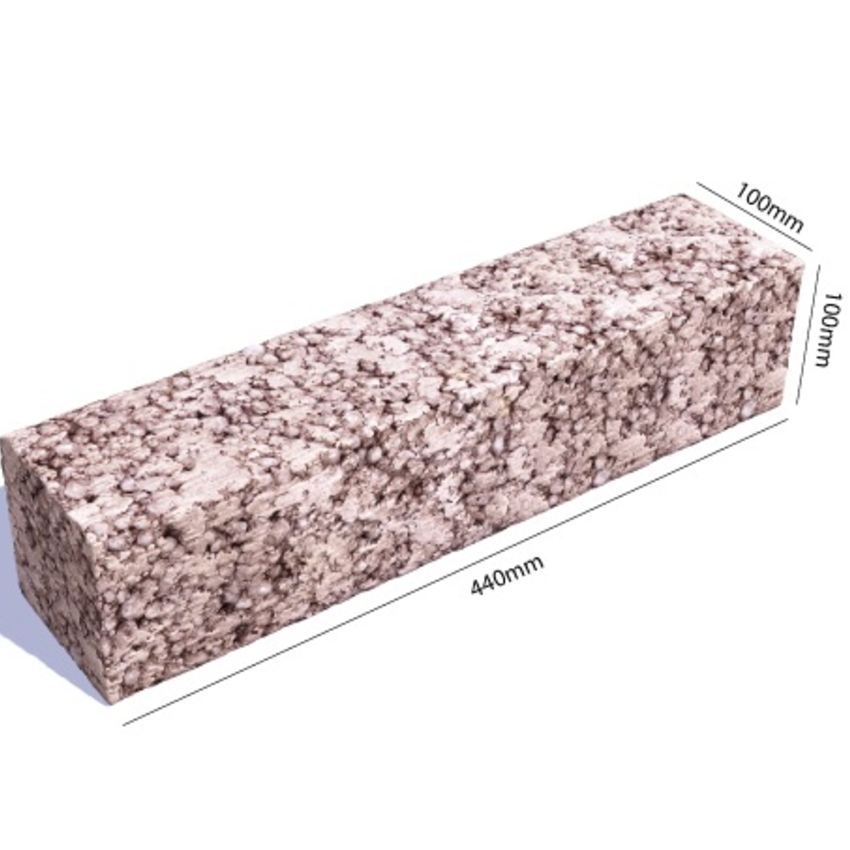

- Liteblock - 100mm - Soap Bar

- Liteblock -100mm Solid

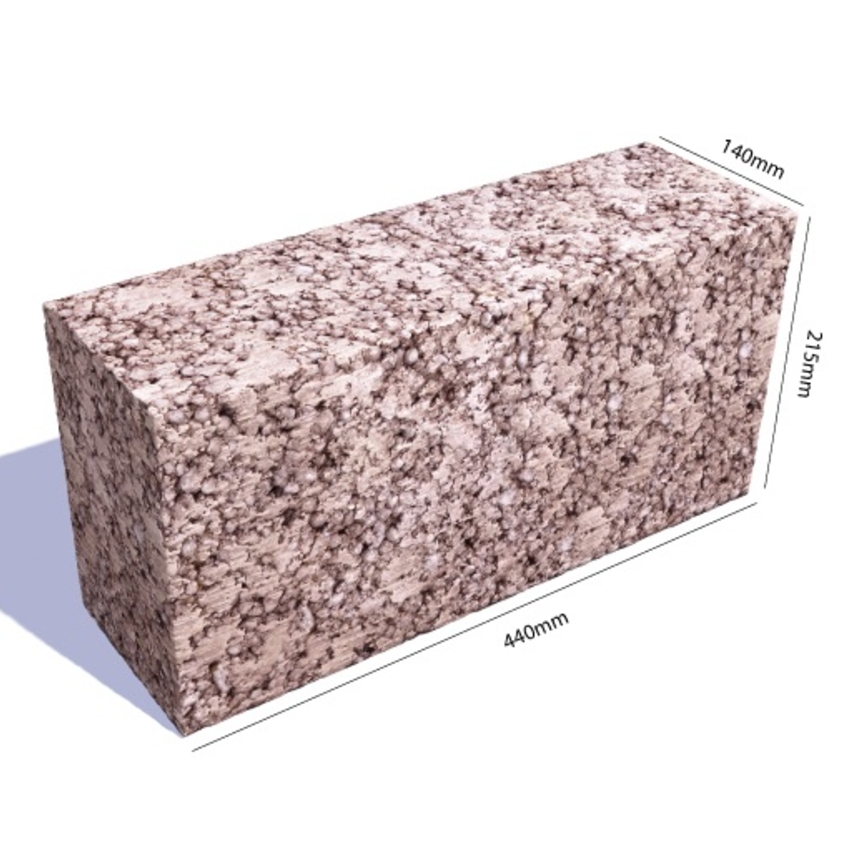

- Liteblock -140mm- Solid

- Liteblock -140mm Soap Bar

- Thermal Liteblock

- Liteblock stock brick

Thermal Liteblock

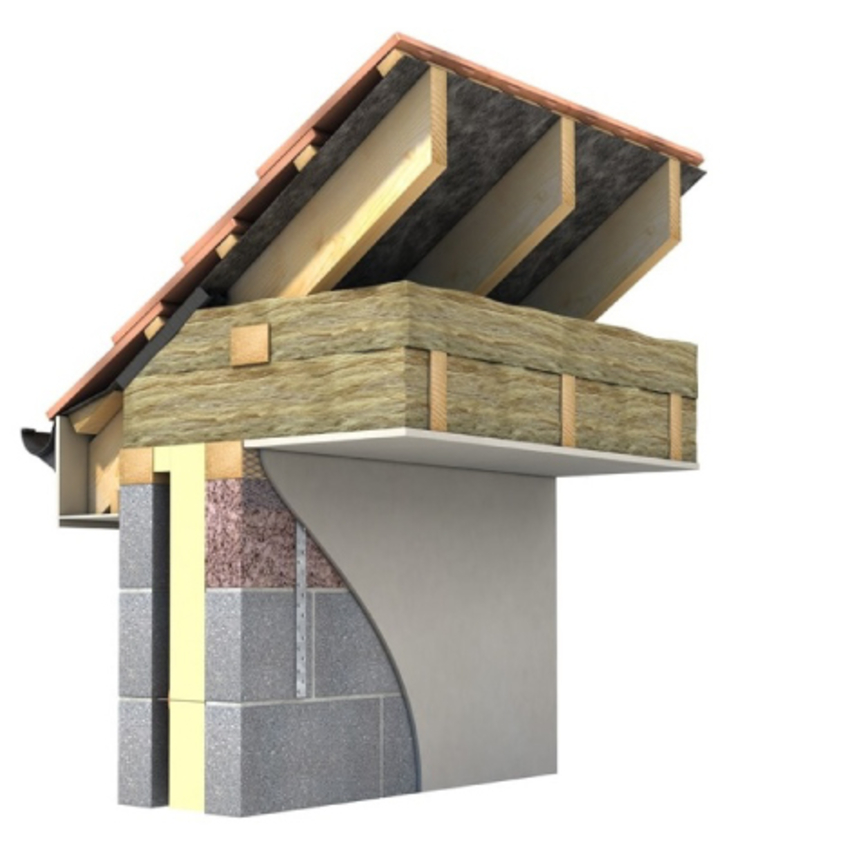

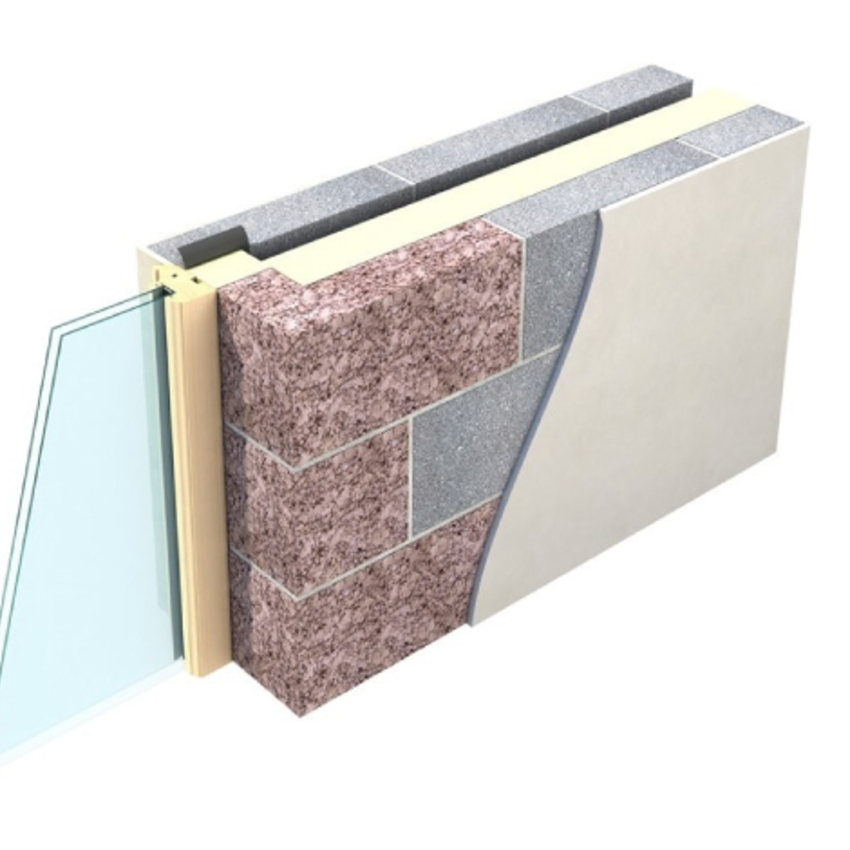

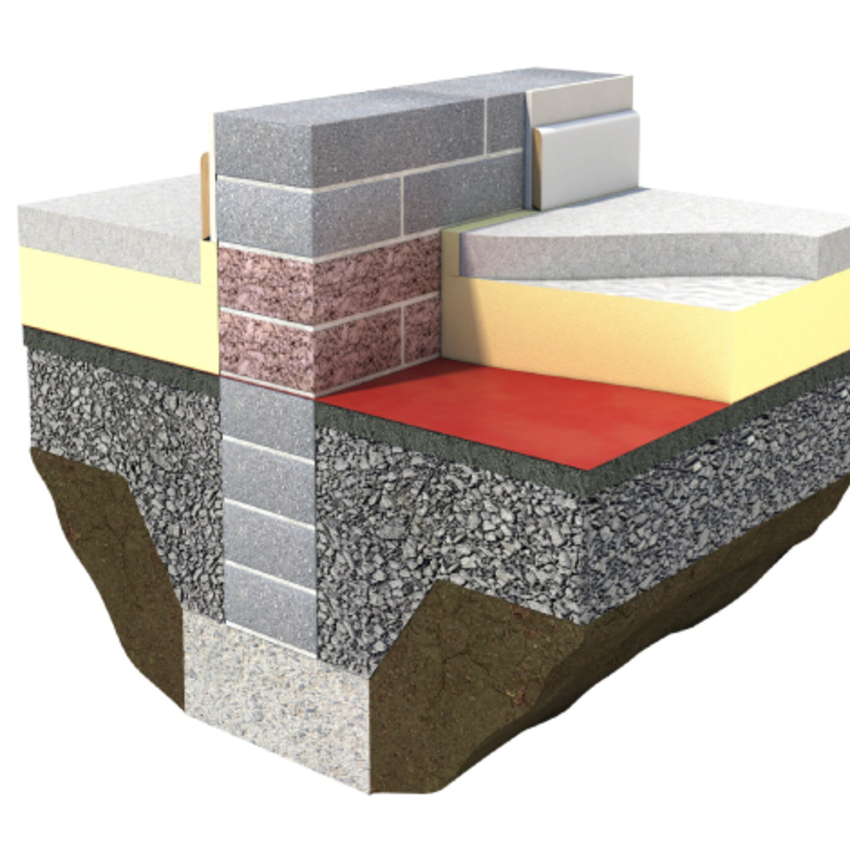

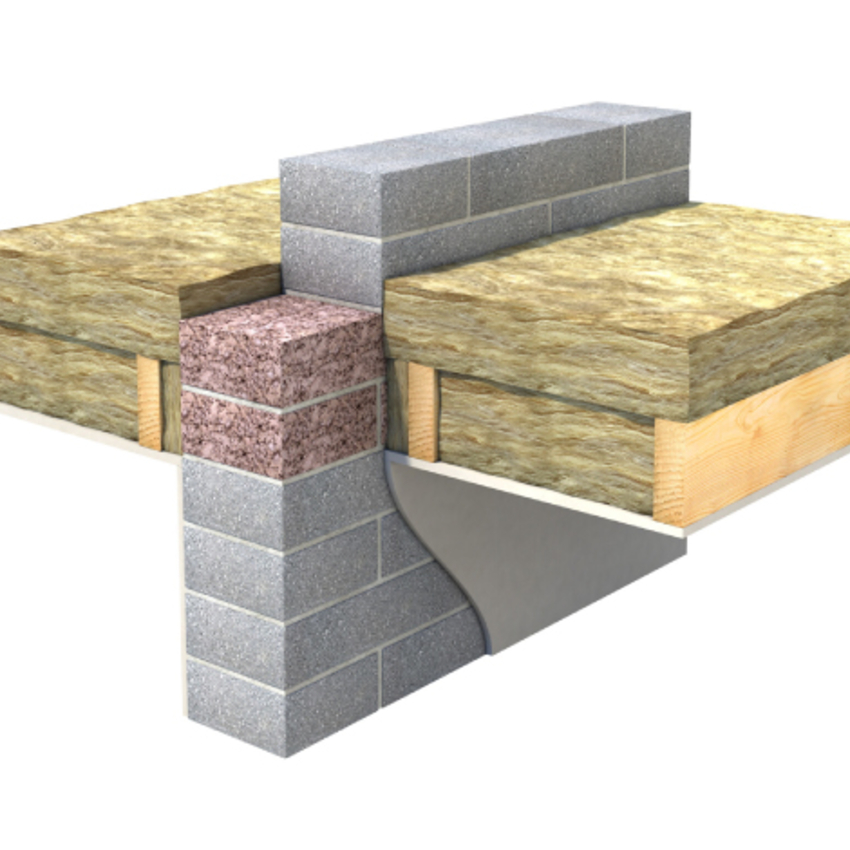

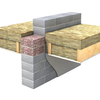

Roadstone 7.5 N Thermal Liteblock is manufactured in Ireland, achieving Thermal conductivity (Lambda λ) values less than 0.33 W/mK, using a special mix which includes light weight aggregates. This mix produces a concrete block with excellent insulation properties, while maintaining structural strength and allowing for traditional construction methods to be used.

The Roadstone Thermal Liteblock system combines the Roadstone Thermal Liteblock with the Roadstone concrete block range, which when used in accordance with the Acceptable Construction Details (ACDs), achieves psi values equal to or better than the standards set out in Technical Guidance Document (TGD) Part L 2019.

Roadstone has thermally modelled all relevant details in appendix D of TGD L 2019. From this extensive research Roadstone are now in a position to provide detail solutions that comply fully with psi value requirements outlined in TGD L 2019- Appendix D.

WINNER Best Interior Building Product - RIAI Architecture Choice Awards

WINNER Best New Product Innovation - Irish Build & Design Awards

WINNER Construction Product of the Year - Irish Construction Industry Awards

Learn about the impact of NZEB on the updated Technical Guidance Document (TGD) Part L 2019, and Roadstone’s solution using the Thermal Liteblock system.

NZEB and Part L compliance using Thermal Liteblock

Nearly Zero Energy Building(NZEB) means a building that has a very high energy performance, as determined in accordance with Annex I. The nearly zero or very low amount of energy required should be covered to a very significant extent by energy from renewable sources, including energy from renewable sources produces on site or nearby.

The NZEB standard as set out in TGD L 2017 Buildings other than dwellings applies to works from 1st January 2019 (subject to transitional arrangements). For Public Sector bodies, NZEB applies from 31st December 2018.

In order to achieve NZEB compliance, it means that buildings will require improved Fabric Efficiency, which can be assisted through the use of Roadstone’s Thermal Liteblock system.

Download the full range of Technical Drawings. Files are compatible with Autocad 2013 and newer.

-

Remote video URL

Remote video URL

What are the benefits to using the Roadstone Thermal Liteblock System in a low energy building, and what is the impact on the Building Energy Rating (BER) results?

To demonstrate the benefits, we need to be clear on what thermal bridging is, and the difference between U value, thermal conductivity (Lambda λ) value, psi (ᴪ) values and how psi (ᴪ) values are used to calculate the overall (y) factor for a building. All of these parametres are used in the Dwelling Energy Assessment Procedure (DEAP) in Ireland, to calculate the overall heat loss through the building fabric.

What is Thermal Bridging?

Thermal bridging is a localised area of the building envelope where the heat flow is increased in comparison with that of adjacent areas, due to junctions where insulation is not continuous. Thermal bridges are weaknesses in the building envelope where thermal energy is transferred at an increased rate compared to the surrounding area.Thermal Bridging is first measured by calculating the psi(ᴪ) value of each junction (see below explanation for psi(ᴪ) value. The sum of the psi(ᴪ) values are then multiplied by the lengths of the bridged junctions, these figures are then used to calculate the overall Thermal Bridging Factor (y value) for any given building.

What is a Lambda (λ) value?

THERMAL CONDUCTIVITY (W/MK)A Lambda value (λ) is a measure of the rate of heat flow through a material (fig 3). It will vary with density, porosity, moisture content and temperature of the material. The units of Thermal Conductivity are expressed in watts per metre

of thickness per degree Kelvin of temperature difference from one side of the material to the other. The lower the number, the less heat passes through the material.

What is an R Value?

THERMAL RESISTANCE (M2 K/W)The R- Value is a measure of the resistance to heat flow of a given thickness of a material (fig 4) or combination of materials, i.e. building plane elements such as a wall, roof or floor.

To calculate the Thermal Resistance (R) of a material, divide the thickness (d) of material by its

lambda value (λ). d/ λ =R.

For example:

Standard Concrete block: λ = 1.33 (W/mk)

Roadstone Thermal Liteblock: λ = 0.33 (W/mk)

What is a U value?

(W/(M2K)The Thermal Transmittance (U value) relates to a building plane element (wall, roof, floor), and is a measure of the rate at which heat passes through one square metre of all of the components combined to make up that structure (fig. 5). The

U value is measured in W/m2K (Watts per square metre Kelvin), where Kelvin (K) is the unit of temperature difference across the elements from inside to outside. A U value = 1 divided by the sum of all the thermal resistances of each component in the structure combined, i.e. 1 / Σ (R) = U.

What is a psi value?

(W/MK)The psi value (ᴪ) is the amount of heat (Watts) lost at a thermal bridge, for every linear metre

(m) of that bridge, multiplied by the temperature difference between outside and inside (degrees Kelvin (K)). The psi value represents the extra heat flow through the linear thermal bridge over and above that through the adjoining plane elements. The psi value figures for any given junction are multiplied by the lengths of those Junctions to calculate the buildings y factor. A psi value for a junction is calculated using 2D and 3D thermal modelling, in accordance with various standards such as BR497, BRE IP 1/06, I.S. EN ISO 6946

I.S. EN ISO 10211, I.S. EN ISO 13370 depending on the junction type.

What is a (y) factor?

The DEAP calculation accounts for thermal bridging at junctions between elements and around The DEAP calculation accounts for thermal bridging at junctions between elements and around openings using a (y) factor. When linear thermal transmittance psi (ᴪ) values are available for openings using a (y) factor. When linear thermal transmittance psi (ᴪ) values are available for element junctions, the psi values can be multiplied by the lengths (l) of their respective junctions element junctions, the psi values can be multiplied by the lengths (l) of their respective junctions (ᴪ X l), and the sum of all the (psi X l) figure is then divided by the total area of building envelope (ᴪ X l), and the sum of all the (psi X l) figure is then divided by the total area of building envelope containing thermal bridging, to calculate the (y). Roadstone can now provide details* and containing thermal bridging, to calculate the (y). Roadstone can now provide details* and corresponding psi values, in line with Paragraph 3 of Appendix K of the DEAP Manual below:Repeating

Repeating (e.g. timber studs with insulation between, at fixed distance centres):Because this type of bridging is constant, the effects of a repeating thermal bridge can be accounted for in a U value calculation.

Random

Random (e.g. one off cold bridge due to penetration of the insulation layer, such as a balcony support bracket, metre box etc).Non-repeating

Non-repeating (e.g. Junctions between floors and walls, walls and roofs, window jambs and heads). Cold bridging at these junctions occurs where the insulation layer is interrupted by non-insulating materials, and heat loss in these areas can lead to reduced surface temperatures causing interstitial and surface condensation to occur.Durability & S.R. 325

The Roadstone Thermal Liteblock is now available in 13N. This increased strength Roadstone Thermal Liteblock is ideal for use in commercial and high-rise residential buildings which have greater structural requirements as well as locations below or near ground level requiring increased durability against freeze/thaw attack. The Roadstone 13N Thermal Liteblock has been rigorously tested for freeze/thaw resistance and satisfies all the durability requirements of S.R. 325 Table 14(A). The Roadstone 13N Thermal Liteblock is a CE marked product, manufactured in our state-of-the-art plant under a registered Quality Management System to I.S. EN ISO 9001 and certified by the NSAI.I.S. EN Compliance

Concrete blocks in Ireland are produced to I.S.EN 771-3 ‘Specification for masonry units – Part

3: Aggregate concrete masonry units (Dense and lightweight aggregates)’. The standard states that when a suitable layer of render is applied which provides a “complete protection against water penetration no reference to freeze/thaw resistance is required”. For this reason there is no concrete block

freeze/thaw resistance EN in place. The standard also states that when relevant “the manufacturer shall evaluate and declare the freeze/thaw resistance of the units by reference to the provisions valid in the intended place of use”. This means it is up to the manufacturer to decide on a suitable freeze/thaw resistance test procedure.

S.R. 325 Compliance

S.R. 325 Table 14 sets out the durability requirements for clay and aggregate concrete masonry units for given exposure conditions. For work below or near external ground level where there is a high risk of saturation with freezing a 13N aggregate concrete block is specified. A minimum block density is also indicated. This combination of higher strength and density satisfies the freeze/thaw durability requirements without the need for costly freeze/ thaw resistance testing. To confirm its suitability for use in these severe exposure conditions the Roadstone 13N Thermal Liteblock has undergone freeze/thaw resistance testing as outlined below.Freeze Thaw resistance explained

The Roadstone 13N Thermal Liteblock has been tested for freeze/thaw resistance using an in-house method based on I.S. EN 772-22 ‘Determination of freeze/thaw resistanceof clay masonry units’. Clay masonry units are typically unrendered and exposed to the elements and therefore require a higher level of freeze/thaw resistance. The test takes

12 days to complete and subjects a saturated masonry panel to 100 cycles of freezing to -15°C and thawing to +10°C, while spraying with water at regular intervals throughout. This is a severe and robust test method and far exceeds the typical freeze/thaw durability requirements of masonry units in Ireland. The Roadstone 13N Thermal Liteblock proved to be exceptionally durable to freeze/thaw attack. Based on the criteria outlined in I.S. EN 772-22 the Roadstone 13N Thermal Liteblock can be classified as Freeze/Thaw Resistance Category F2 (suitable for use in severe exposure conditions) and therefore satisfies the freeze/thaw durability requirements of S.R. 325 Table 14(A).

Advantages

Traditional concrete blockLight weight

Reduced thermal bridging

λ< 0.33W/mK

High strength

Freeze/thaw resistance tested

S.R. 325 Table 14(A) durability compliant

Retains strength when wet

Accepts standard block fixings

What is a Roadstone Thermal Liteblock?

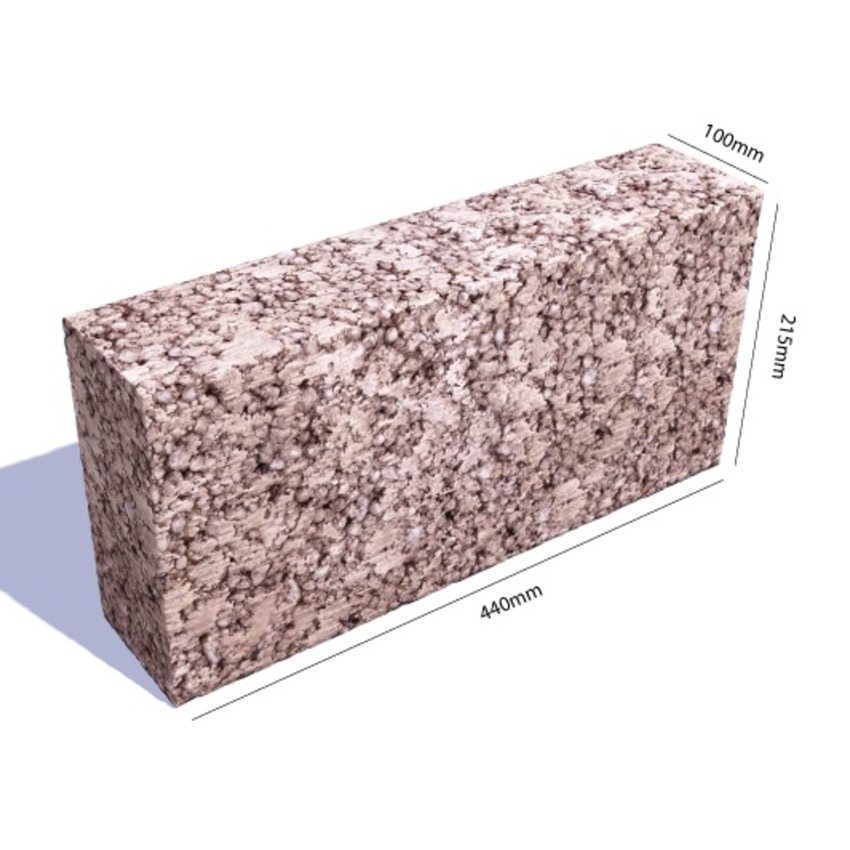

A lightweight concrete block with an excellent thermal conductivity (Lambda λ) value as low as 0.33W/mk.What is the strength, weight and size of the block ?

Compressive Strength 7.5N/mm2Weight 11.2kg

Dimensions 440mm(L) x 100mm(W) x 215mm(H

What is the thermal conductivity (Lambda λ) value of Thermal Liteblock

The 7.5N Thermal Liteblock value is 0.33W/mk.The 13N Thermal Liteblock value is 0.35W/mk

What is Part L of the Building Regulations?

The requirements regarding conservation of fuel and energy for new dwellings are laid out in Building Regulations (Part L Amendment) Regulations 2019 including the limitation of thermal bridging in the building fabric.What is fabric first approach?

Energy efficient design begins with a fabric first approach whereby the buildings shape, orientation, thermal mass and a focus on detailing that limits thermal bridging will save energy.What is a Y factor calculation ?

The DEAP calculation accounts for thermal bridging at junctions between building plane elements and around openings using a (y) factor.What is a thermal bridge ?

Thermal bridging is a localised area of the building envelope where the heat flow is increased in comparison with that of adjacent areas due to the discontinuation of insulation at building junctions.Where do I use Roadstone Thermal Liteblocks ?

The Roadstone Thermal Liteblock is required at key junctions to provide reductions in thermal bridging and heat loss.Do I need to use a special mortar / plaster ?

Roadstone Thermal Liteblock provides excellent adhesive properties with traditional mortars and renders.Is the Roadstone Thermal Liteblock CE marked?

The Roadstone Thermal Liteblock is CE marked in accordance with the requirements of I.S. EN771-3 to system 2+.Where can I get technical info on Thermal Liteblocks?

Roadstone has a dedicated technical team to deal with enquiries on the requirements Part L of the Building Regulations and our solution- Thermal Liteblock.Contact 01-4041200

How will I get the construction details for my house ?

Please contact our technical team to discuss your building project and to access certified construction details.Colin Doyle – 01 404 1200